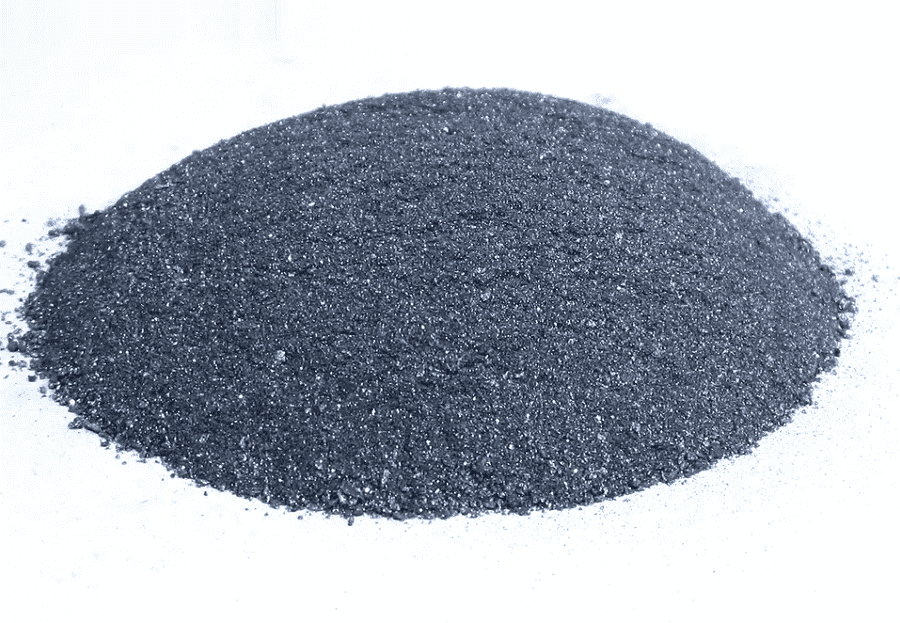

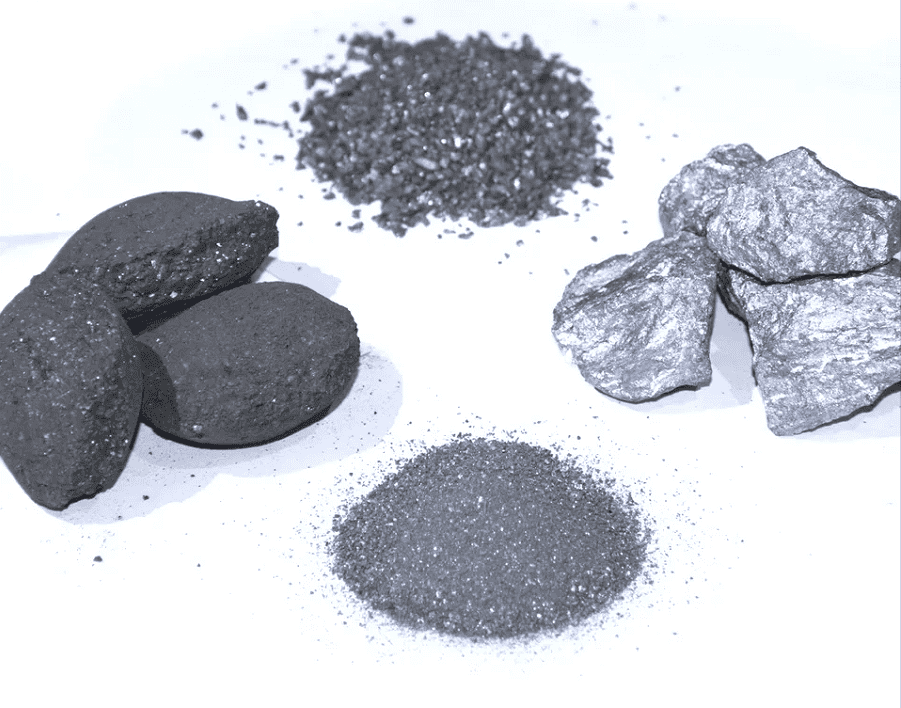

Excellent Quality Ferro Silicon particle For Casting

use

(1) Ferro silicon particles can not only be used in the steelmaking industry but also as a commonly used metallurgical material in the cast iron industry. This is mainly because ferro silicon particles can be used by cast iron manufacturers to replace inoculants and spheroidizers. In the cast iron industry, the price of ferro silicon particles is much lower than that of steel and they are more easily melted, making them a high-quality cast iron alloy product. High quality ferro silicon particle inoculant with uniform particle size and good inoculation effect during casting can promote graphite precipitation and spheroidization, making it a necessary metallurgical material for producing ductile iron.

(2) Used as deoxidizer and alloying agent in steelmaking industry. The chemical affinity between silicon and oxygen is very large, so ferro silicon particles are strong deoxidizers in steelmaking for precipitation and diffusion deoxidation. In the steelmaking industry, it is often used as an ingot cap heating agent to improve the quality and recovery of ingot by using the characteristic that ferrosilicon grains can release a lot of heat from the ene burning at high temperature.

Ferro Silicon particle for stainless steel production

1. Low price and easy to melt

ferro silicon particles can not only be used in the steelmaking industry but also in the cast iron industry often used metallurgical materials, mainly because ferro silicon particles can be used by cast iron manufacturers instead of inoculants and nodulators, in the cast iron industry, the price of ferro silicon particles is much lower than steel, and more easily melted, is a ferroalloy product with casting capacity.

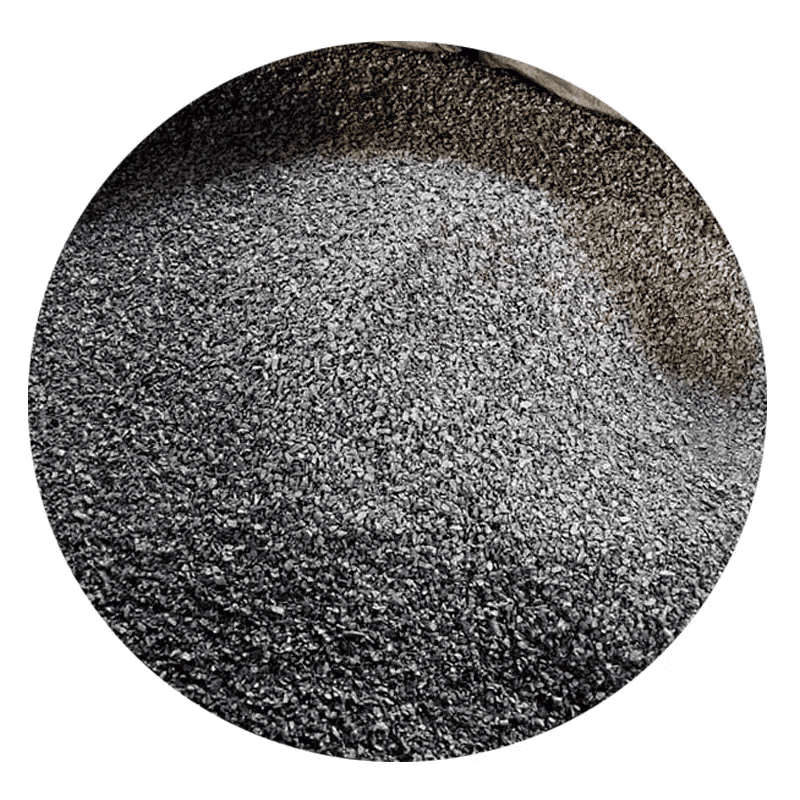

2. Uniform particle size

Ferro Silicon particles have no fine powder, stable inoculation effect, and a small tendency to produce slag. The heaviest is that they have the characteristics of other inoculants and have lower costs.

3. Good elasticity and plasticity

Its low elasticity is due to its low bending performance, and its tensile strength is several times higher than that of ordinary mild steel materials. The ferro silicon particle also has excellent corrosion resistance, and its protective coating layer can effectively prevent the surface corrosion of the casting.

4. Good machinability

Ferro silicon particles have good mechanical processing properties, can quickly complete complex processing tasks, and have good stability and wear resistance, as well as a long service life. That is to say, ferro silicon particles have good mechanical properties and almost zero residue properties, which make them ideal casting materials for the casting industry.

5. Excellent thermoplastic properties

Ferro silicon particles have excellent thermoplastic properties, can resist deformation under various high temperature conditions, and can maintain their strength at higher temperatures, making them particularly suitable for use in the production of thermoplastic castings.

Chemical element

|

Item% |

Si |

P |

S |

C |

AI |

|

≤ |

|||||

|

FeSi75 |

75 |

0.03 |

0.02 |

0.15 |

1 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.15 |

0.5 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.1 |

0.1 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.05 |

0.05 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.02 |

0.02 |

|

FeSi72 |

72 |

0.03 |

0.02 |

0.15 |

1 |

|

FeSi72 |

72 |

0.03 |

0.02 |

0.15 |

0.5 |

Notice:Production of different specifications of silicon calcium alloy according to customer requirements