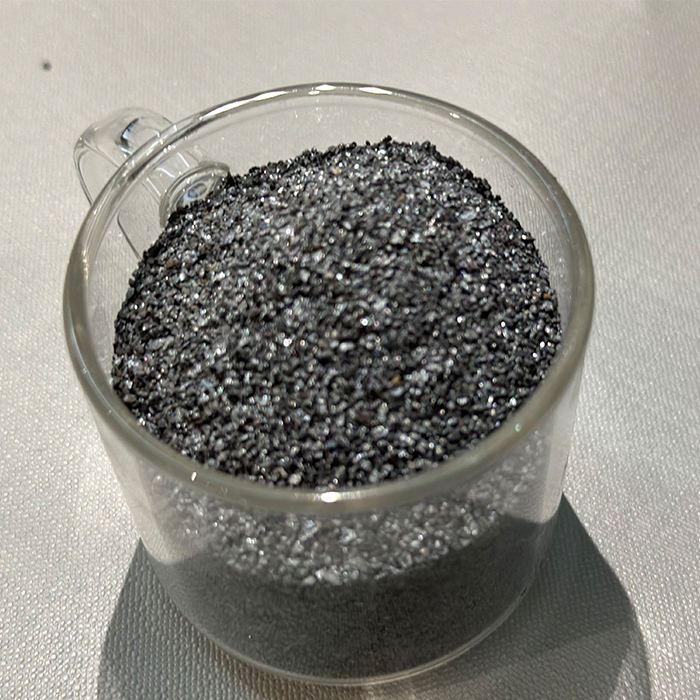

Ferrosilicon powder 72% 75% ferro silicon inoculant Fesi6.5 fesi Alloy Soft magnetic material

Use of ferrosilicon powder

It is used as reducing agent in ferroalloy production. Not only is the chemical affinity between silicon and oxygen very high, but also the carbon content of high silicon ferrosilicon is very low. Therefore, high silicon ferrosilicon (or siliceous alloy) is a reducing agent commonly used in the production of low-carbon ferroalloy in the ferroalloy industry.

The ground or atomized ferrosilicon powder can be used as the suspended phase in the mineral processing industry. It can be used as the coating of welding rod in the welding rod manufacturing industry. High silicon ferrosilicon can be used to manufacture silicone and other products in the chemical industry.

Advantages of ferrosilicon

Ferrosilicon powder is generally rolled with high-silicon ferrosilicon. In the process of electric furnace steelmaking, ferrosilicon powder is used for diffusion deoxidation. The expansion deoxidation is carried out on the surface of slag steel, so the use of ferrosilicon powder as a deoxidizer is not easy to pollute the molten steel and reduces the content of inclusions in the steel. The higher the silicon content in ferrosilicon, the lighter its weight. For example, ferrosilicon with a silicon content of 45 percent has a specific gravity of 5.15, while ferrosilicon with a silicon content of 75 percent has a specific gravity of 3.5.

The ferrosilicon powder rolled by ferrosilicon is relatively heavy. After being added, it can quickly enter the molten steel for precipitation and deoxidation to increase silicon in molten steel. The ferrosilicon powder rolled with high ferrosilicon is lighter, which is very conducive to diffusion deoxidation. Moreover, the higher the silicon content, the stronger the deoxidation effect. Therefore, ferrosilicon powder is generally made of high-silicon ferrosilicon by rolling.

When the ferrosilicon powder is first added, it has little effect on the heating time of the molding sand, but it has a significant impact on the heating temperature and the strength of the plastic sand after hardening. With the increase of ferrosilicon powder addition, the heating temperature and strength increase, the higher the silicon content in ferrosilicon, the finer the particle size, the less surface oxidation, and the stronger its effect.

Chemical element

|

Item% |

Si |

P |

S |

C |

AI |

|

≤ |

|||||

|

FeSi75 |

75 |

0.03 |

0.02 |

0.15 |

1 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.15 |

0.5 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.1 |

0.1 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.05 |

0.05 |

|

FeSi75 |

75 |

0.03 |

0.02 |

0.02 |

0.02 |

|

FeSi72 |

72 |

0.03 |

0.02 |

0.15 |

1 |

|

FeSi72 |

72 |

0.03 |

0.02 |

0.15 |

0.5 |

Note: Different specifications of ferrosilicon can be produced according to customer requirements