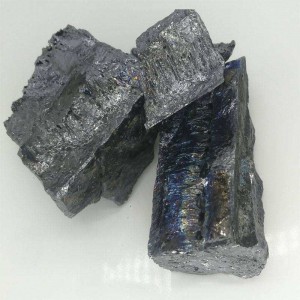

Manganese Metal Mn Lump Mn Shipping Timely Manganese For Steelmaking

Application

1. For the smelting of copper alloys, a large amount of manganese is required. Also, the composition is easy to be accurately controlled.

2. Electrolytic metal manganese iswidely used in manganese copper alloys, manganese aluminum alloys and 200 series stainless steels. Manganese can improve the hardness, strength, toughness, wear resistance and corrosion resistance of metal materials.

3. Because of its high purity and low impurities, electrolytic metal manganese has been successfully and widely used in various fields such as iron and steel smelting, non-ferrous metallurgy, electronic technology, chemical industry, environmental protection, food hygiene, welding electrode industry and aerospace industry

Advantages of manganese metal

The electrolytic manganese features high purity and is often used to increase the hardness of alloy. It has been widely used in manganese-copper alloy, manganese-aluminum alloy, and 200 series stainless steel to improve their strength, toughness, wear resistance, and corrosion resistance.

Chemical Element

|

Electrolytic Manganese Metal Flakes |

|||||||

|

Product Grades |

Chemical element | ||||||

|

Mn(%min) |

C(%max) |

S(%max) |

P(%max) |

Fe(%max) |

Si(%max) |

Se(%max) |

|

|

≥(Min) |

≤(Max) |

||||||

|

Mn99.9 |

99.93 |

0.01 |

0.02 |

0.0006 |

0.0022 |

0.0003 |

0.037 |

|

Mn99.8 |

99.8 |

0.02 |

0.03 |

0.005 |

0.03 |

0.005 |

0.06 |

|

Mn99.70 |

99.7 |

0.04 |

0.05 |

0.005 |

0.03 |

0.005 |

0.10 |

|

Electrolytic manganese metal |

|||||||

|

Model |

Mn(%min) |

C(%max) |

S(%max) |

P(%max) |

Fe(%max) |

Si(%max) |

Se(%max) |

|

Mn99.95 |

99.95 |

0.01 |

0.03 |

0.001 |

0.006 |

0.002 |

0.0003 |

|

Mn99.80 |

99.80 |

0.02 |

0.03 |

0.005 |

0.003 |

0.005 |

0.06 |

|

Mn99.70 |

99.70 |

0.04 |

0.05 |

0.005 |

0.003 |

0.010 |

0.10 |

|

Mn99.50 |

99.50 |

0.08 |

0.10 |

0.10 |

0.05 |

0.015 |

0.15 |