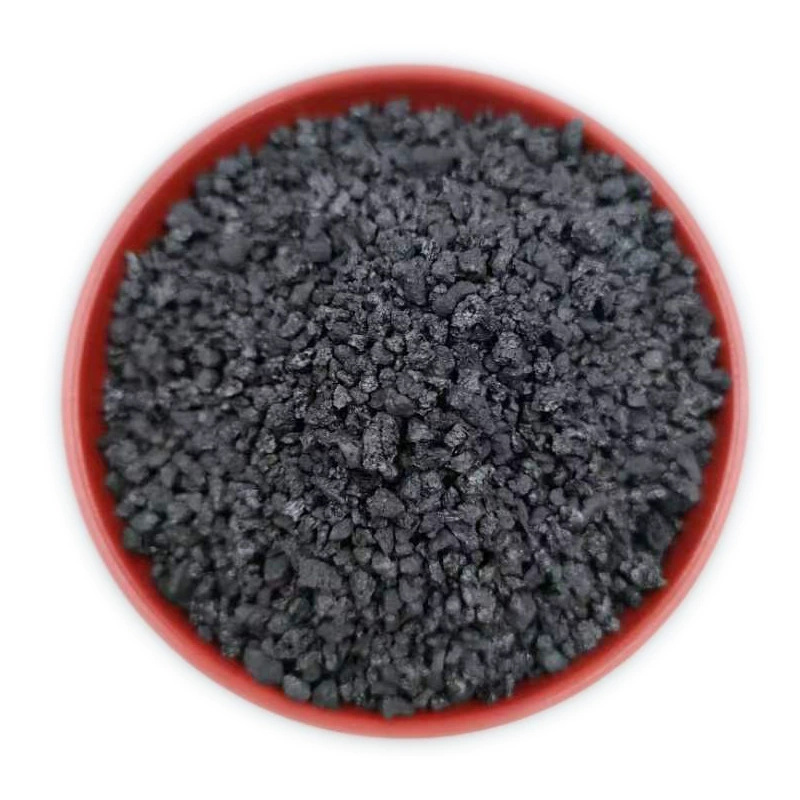

Petroleum coke Recarburizer for steel Melting High Carbon of Green graphitized calcined for Metallurgy and Foundry

product characteristics

High fixed carbon content, low sulfur contentstable carbon addition effect and high carbon yield. Scope of application:

Being used for the carburizing of a variety of electric smelting furnace to cast steel and iron.

Grain size:l

Common grain size:0-1mm, it can supply goods meet users demands.

Using methods

Adjust carbon points,put into the centrai lower part of furnace with metal materials,the yield car reach 90%-95%;

Acust the carbon after the molten steel meit, put it on the surface of moiten steel. finally,the rate is about 66% by riten steel’ s swirt stirring or artificial mixing.

Technicalindicators:

| Compositions | F.C | S | Volatile matter | Ash content | Moisture |

| carburant92 | ≥92 | ≤0.3 | ≤0.1 | ≤2 | ≤1 |

| carburant90 | ≥90 | ≤0.3 | ≤0.1 | ≤2 | ≤1 |

| Compositions | F.C | S | Volatile matter | Ash content | Moisture |

| carburant98 | ≥98 | ≤0.3 | ≤0.5 | ≤0.5 | ≤0.7 |

| Compositions | F.C | S | Volatile matter | Ash content | Moisture |

| carburant95 | ≥95 | ≤0.05 | ≤1 | ≤7 | ≤1 |

| carburant92 | ≥92 | ≤0.05 | ≤1 | ≤ | ≤1 |

Advantages of carburizers

High fixed carbon, high absorption rate

Low-sulfur and low-nitrogen, and the absorption speed is faster than similar graphitized recarburizers, and it does not adsorb to the furnace wall and absorbs completely without residue. The price is lower than similar low-sulfur products, and the price is high.

1. The absorption rate is high, and the absorption rate can reach more than 90% or even higher according to the application method.

2. The absorption speed is fast, which is faster than that of similar graphitized recarburizers. It does not adsorb to the furnace wall and has no residue, and the absorption speed of recarburization in the furnace is more obvious.

3. Low sulfur content, below 0.05%, or even lower, low nitrogen content, below 300PPM.

4. Super high cost performance is very competitive in price among similar products.